https://www.thingiverse.com/thing:7160423/files

You will need a # 1 Screwdriver

You will need a # 1 Screwdriver iFixit Jimmy, or similar thin tool (like a guitar pick) to pry

iFixit Jimmy, or similar thin tool (like a guitar pick) to pry #51, 1/8". 3/16" and 7/32" drill bits

#51, 1/8". 3/16" and 7/32" drill bits A drill bit holder

A drill bit holder A soldering iron (I love my Hakko

FX88DX, but any small soldering

iron will do)

A soldering iron (I love my Hakko

FX88DX, but any small soldering

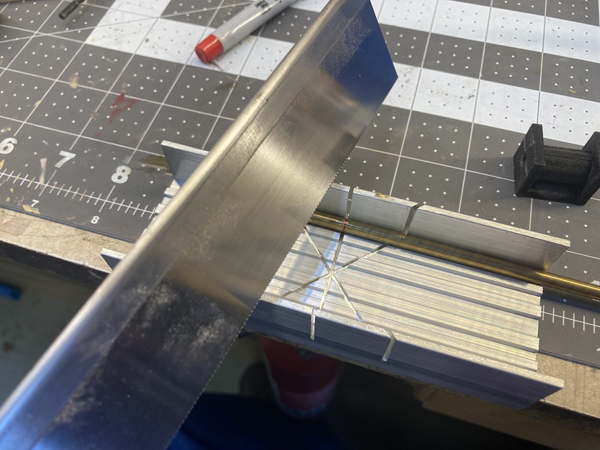

iron will do) A razor saw or some other way to cut metal bar and tubing. A

cheap aluminum miter box is

helpful

A razor saw or some other way to cut metal bar and tubing. A

cheap aluminum miter box is

helpful A 3d Printer or access to one. I used a Bambu

Mini-A1 which has been rock solid for me. (Not an affiliate link, I just recommend

this printer)

A 3d Printer or access to one. I used a Bambu

Mini-A1 which has been rock solid for me. (Not an affiliate link, I just recommend

this printer)  You will need a Flysky Fs-i6X radio or

equivalent. This conversion my fit other Flysky radio in

that series, but has not been tested.

You will need a Flysky Fs-i6X radio or

equivalent. This conversion my fit other Flysky radio in

that series, but has not been tested.  K&S brass tubing 7/32"

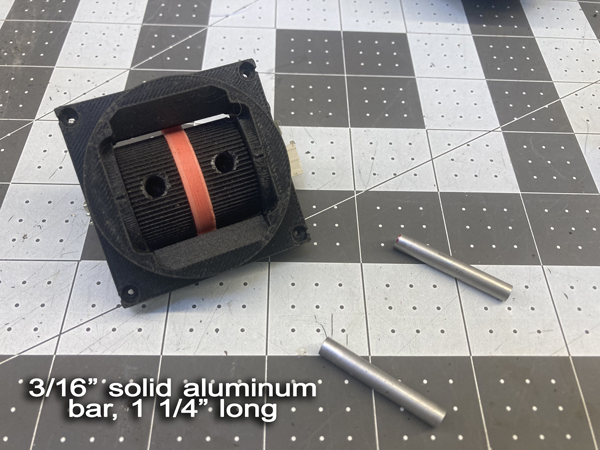

K&S brass tubing 7/32" 3/16 diameter solid brass or

stainless steel round bar

3/16 diameter solid brass or

stainless steel round bar 3/16 diameter solid aluminum round bar

3/16 diameter solid aluminum round bar Thin solder (I like .032 diameter 63/37 flux core solder if you can

find it)

Thin solder (I like .032 diameter 63/37 flux core solder if you can

find it) Soldering flux - highly

recommended for better flow, even if you are using flux core solder

Soldering flux - highly

recommended for better flow, even if you are using flux core solder Thin heat shrink tubing

Thin heat shrink tubing 9 inches of 24 gauge or similar stranded (flexible) wire

9 inches of 24 gauge or similar stranded (flexible) wire Small Screws; 6 1.7mm x 8mm self tapping screws, and 4 2.3mm x 10mm self tapping screws (this is the assortment

I purchased for this project that has them)

Small Screws; 6 1.7mm x 8mm self tapping screws, and 4 2.3mm x 10mm self tapping screws (this is the assortment

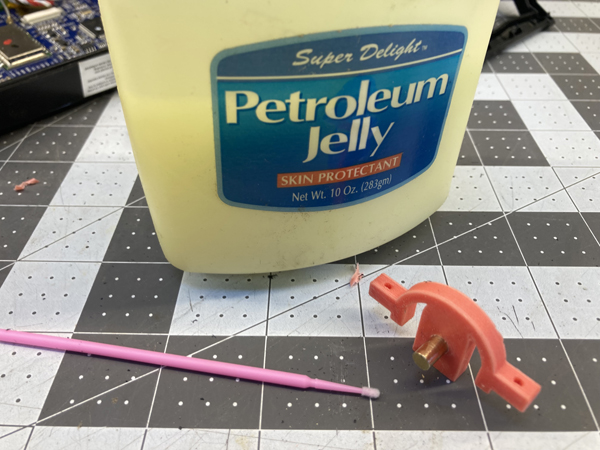

I purchased for this project that has them)  Small amount of Vaseline

Small amount of Vaseline Black RTV sealant

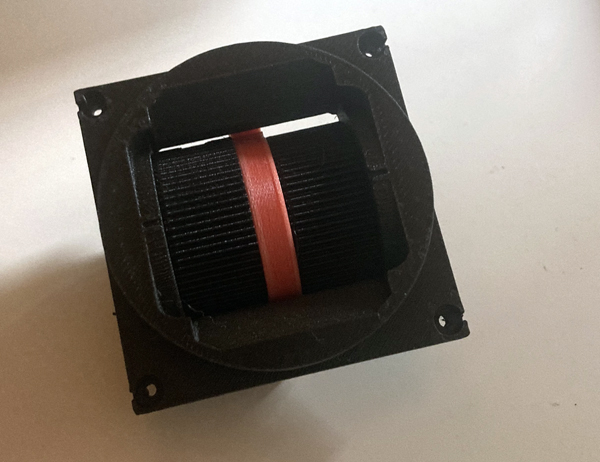

Black RTV sealant Filament for the printer. I

recommend PETG,

which is what I used. The color is up to you, but I found

that black looks nice with this radio, a contrasting center

support will look sharp, perhaps in red.

Filament for the printer. I

recommend PETG,

which is what I used. The color is up to you, but I found

that black looks nice with this radio, a contrasting center

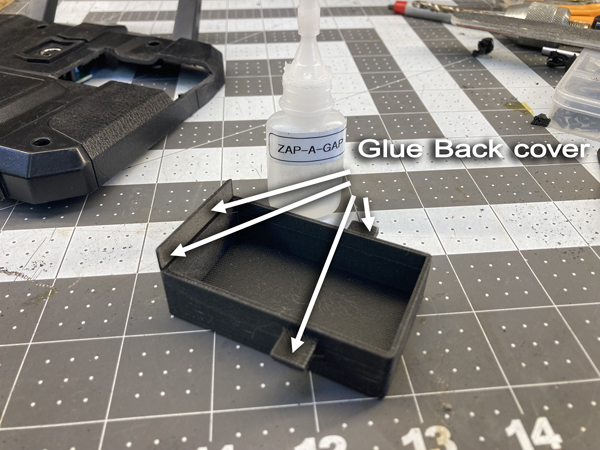

support will look sharp, perhaps in red.  Medium viscosity CA glue. I use Zap-A- Gap.

Medium viscosity CA glue. I use Zap-A- Gap. Thin CA glue.

Thin CA glue.  Sanding stick or metal file to chamfer the edges of the metal parts as

indicated

Sanding stick or metal file to chamfer the edges of the metal parts as

indicated A Fine point Sharpie felt pen

A Fine point Sharpie felt pen A pencil

A pencil

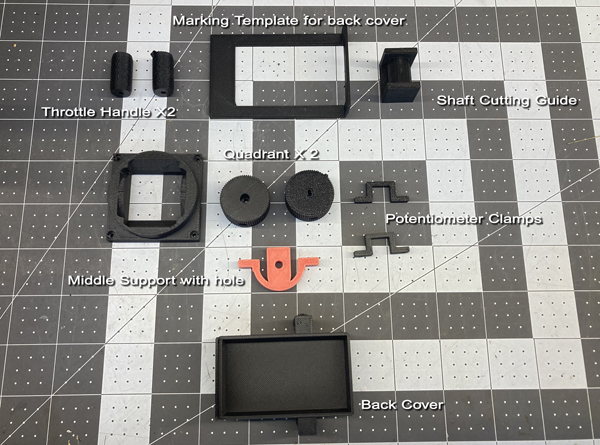

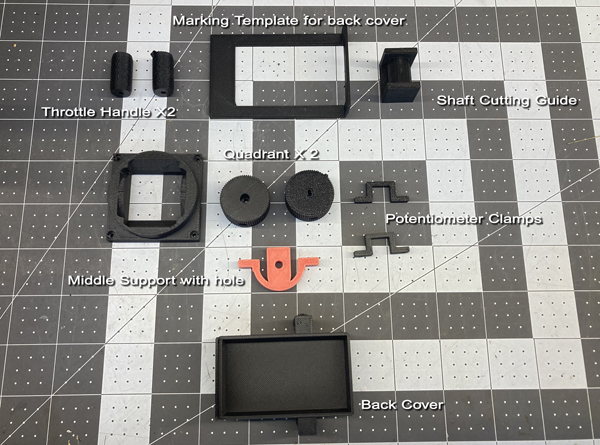

Quadrants

Quadrants Throttle handle

Throttle handle Bezel

Bezel Marking Template

Marking Template Shaft cutting Guide

Shaft cutting Guide Middle Support with Hole

Middle Support with Hole Drill guide

Drill guide Back Cover

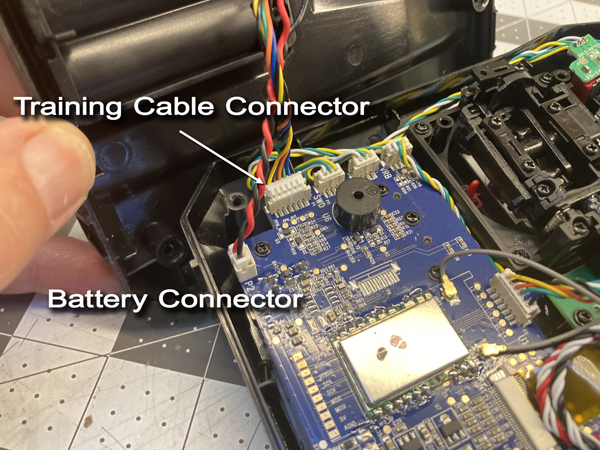

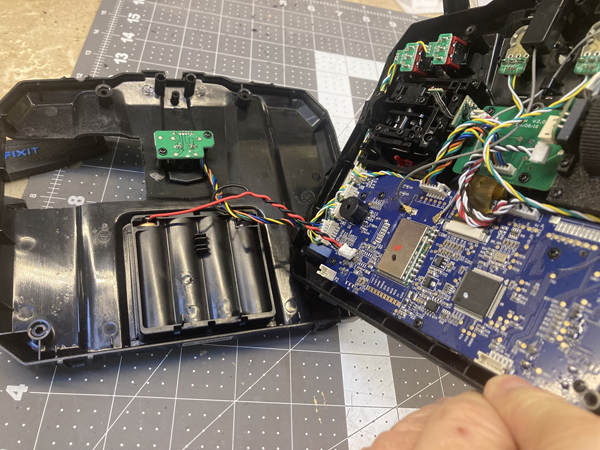

Back Cover Remove the batteries to the transmitter

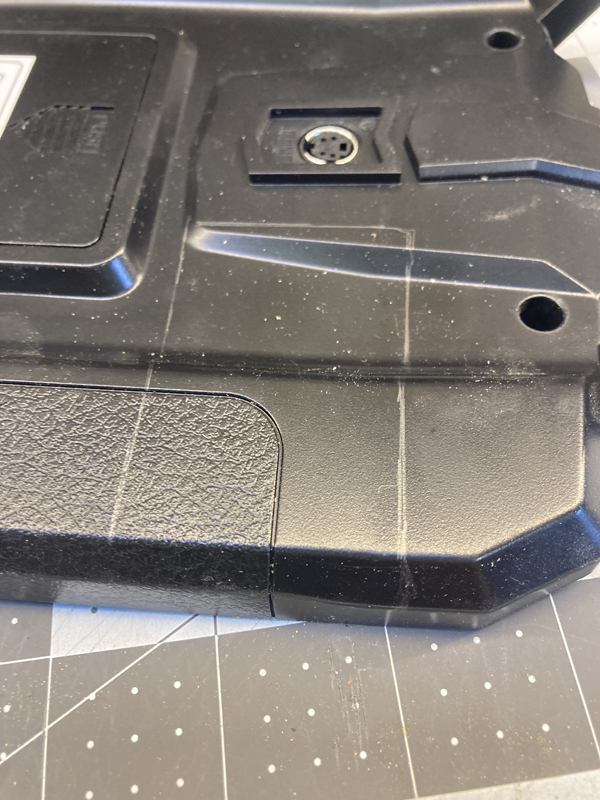

Remove the batteries to the transmitter Take the back of the radio off by removing 4 screws and gently prying

the radio halves away from each other. A guitar pick or other

thin flat tool is useful for this, as is a dedicated pry tool, like the

iFixit Jimmy

Take the back of the radio off by removing 4 screws and gently prying

the radio halves away from each other. A guitar pick or other

thin flat tool is useful for this, as is a dedicated pry tool, like the

iFixit Jimmy .

.

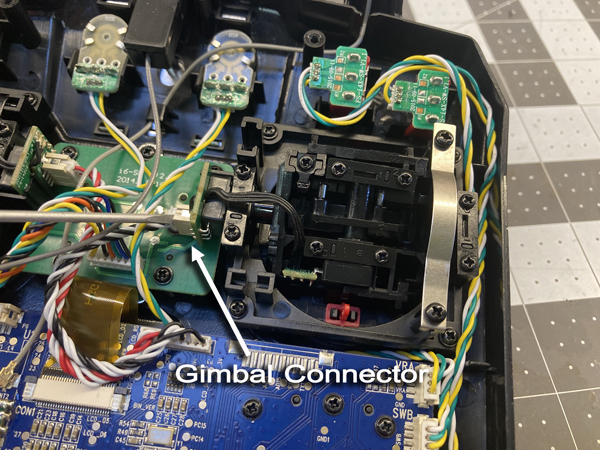

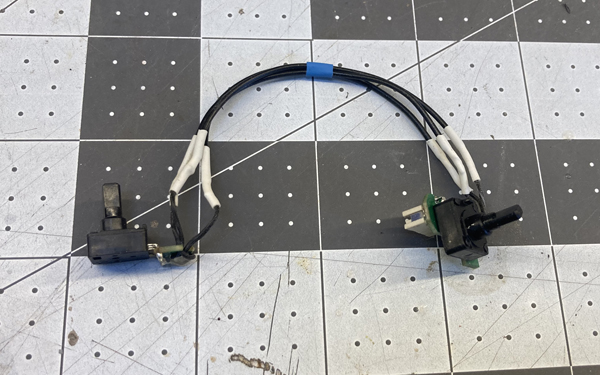

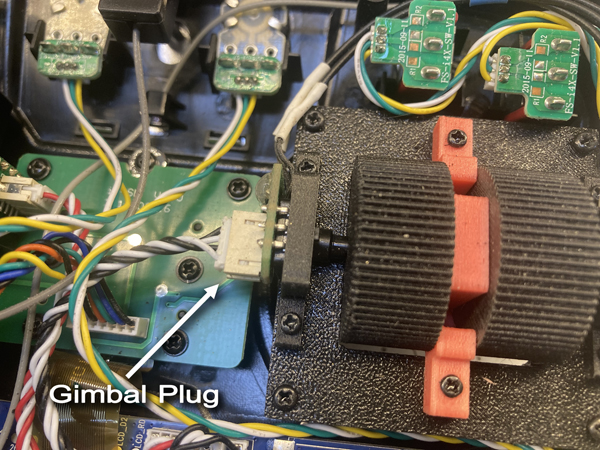

Unplug the four pin connector from left side of the existing gimbal

assembly

Unplug the four pin connector from left side of the existing gimbal

assembly

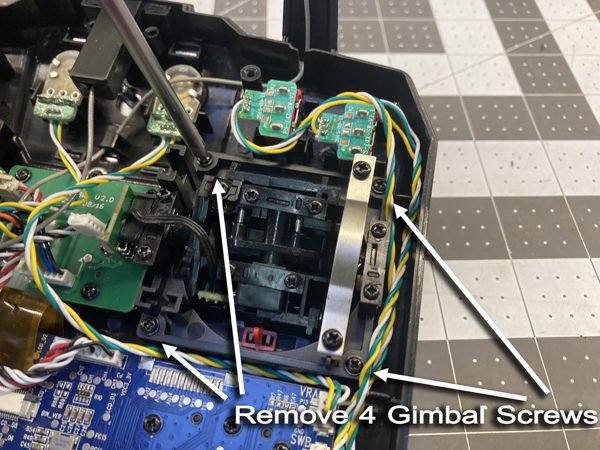

Remove the four screws holding the gimbal assembly to the transmitter.

Remove the four screws holding the gimbal assembly to the transmitter.

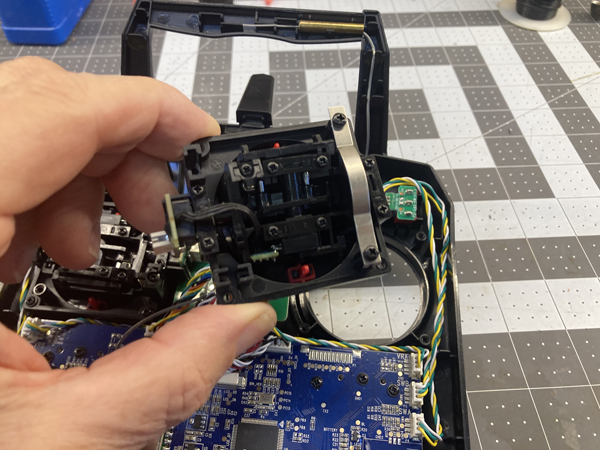

Remove the gimbal from the transmitter.

Remove the gimbal from the transmitter.

Place transmitter and rear cover away from the workbench to protect it

from metal filings and powder from future steps.

Place transmitter and rear cover away from the workbench to protect it

from metal filings and powder from future steps.

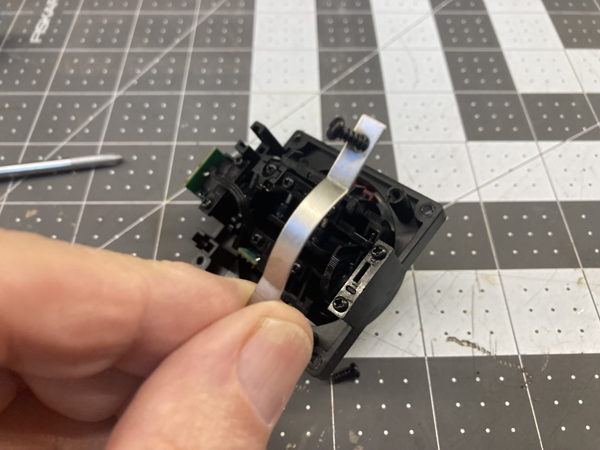

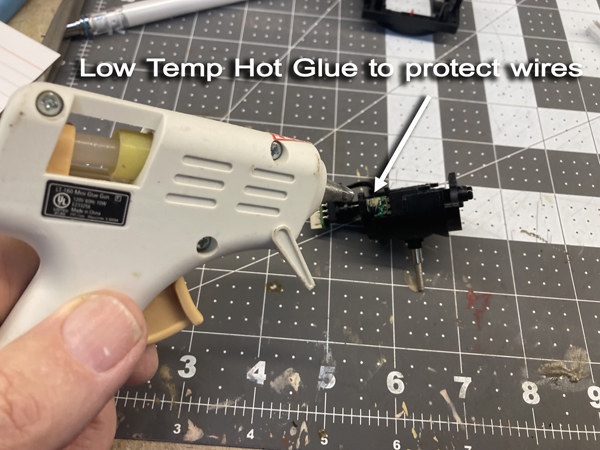

At this point I have found it helpful to reinforce the wires where they

exit the pots with a drop of hot melt glue on each pot circuit board,

encapsulating those wires. Let it cool

At this point I have found it helpful to reinforce the wires where they

exit the pots with a drop of hot melt glue on each pot circuit board,

encapsulating those wires. Let it cool

Remove the two potentiometers. Be careful to not stress the

solder connections to the small circuit boards.

Remove the two potentiometers. Be careful to not stress the

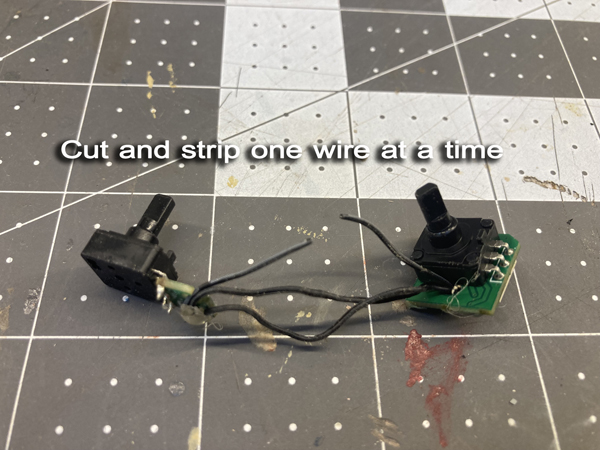

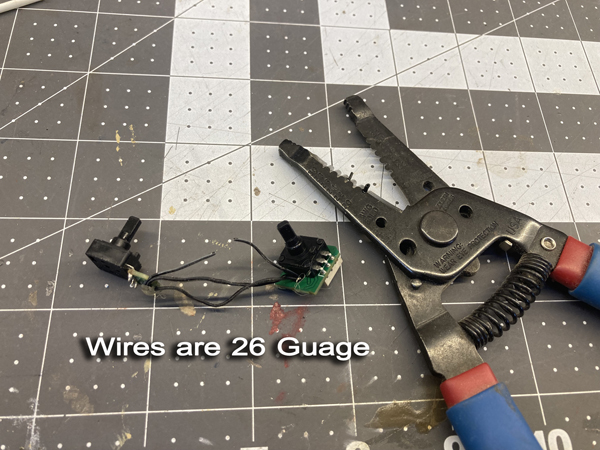

solder connections to the small circuit boards.  There are three 26 guage wires that connect the two potentiometers

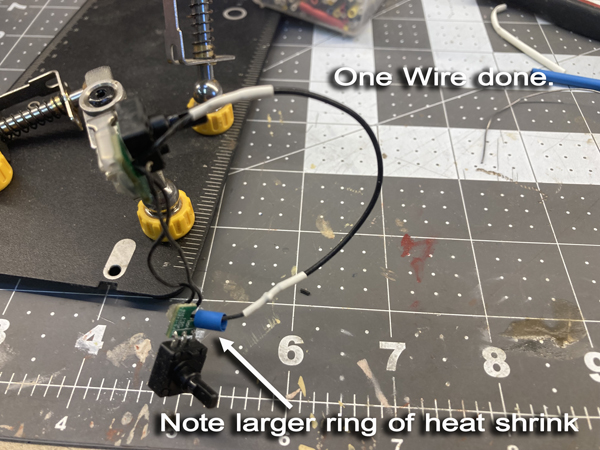

together. Cut them, one at a time, and insert a 3 1/2"

extension between each. Make sure you have a good connection and

cover them with heat shrink tubing. Don't forget to slide

the heat shrink on before you solder! Use a heat gun and

shrink both ends before proceeding.

There are three 26 guage wires that connect the two potentiometers

together. Cut them, one at a time, and insert a 3 1/2"

extension between each. Make sure you have a good connection and

cover them with heat shrink tubing. Don't forget to slide

the heat shrink on before you solder! Use a heat gun and

shrink both ends before proceeding.

Complete extending the wires for the other two pot wires.

Complete extending the wires for the other two pot wires.

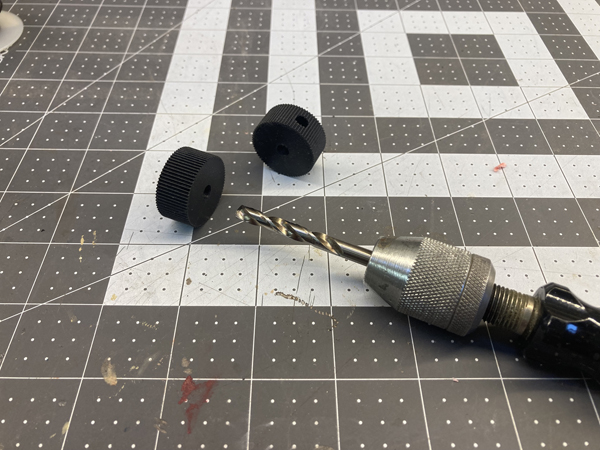

Using the # 51 drill bit, open the holes in the potentiometer

sadles. Also open the holes in the bezel mounting holes,

and the Center support with Hole mounting holes at either end of the

support. You don't have to open any holes on the inside face of

the bezel, just the four that on the side that will face out towards

you when the transmitter is assembled.

Using the # 51 drill bit, open the holes in the potentiometer

sadles. Also open the holes in the bezel mounting holes,

and the Center support with Hole mounting holes at either end of the

support. You don't have to open any holes on the inside face of

the bezel, just the four that on the side that will face out towards

you when the transmitter is assembled.

Using a 7/32" bit, clean out the round hole on the inside of the

two quadrants. It should be pretty close to size, but I like to

bore out to the final dimension due to variations in

printing. Make sure you bore from the large hole side, not

the narrow, smaller side.

Using a 7/32" bit, clean out the round hole on the inside of the

two quadrants. It should be pretty close to size, but I like to

bore out to the final dimension due to variations in

printing. Make sure you bore from the large hole side, not

the narrow, smaller side.

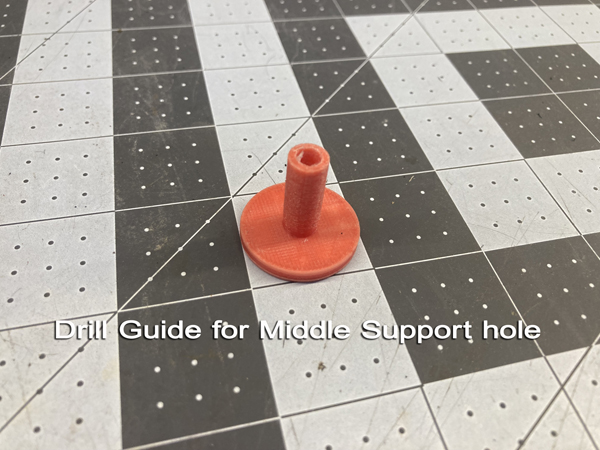

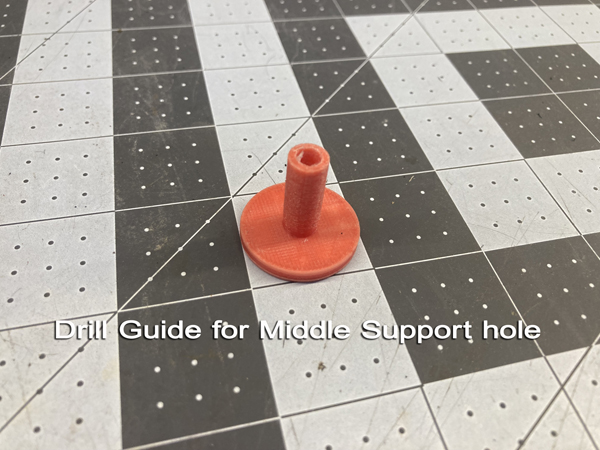

Using the 3/16" drill bit, clean out the hole in the middle

support

with hole part. If you have a drill press, use that,

otherwise use the drill guide that is included in the printing files.

Take your time, if the hole is not perpendicular the shaft will

be out of alignment, which can cause your quadrants to bind upon

assembly. If you need to, print a couple to make sure you

get thiis correct.

Using the 3/16" drill bit, clean out the hole in the middle

support

with hole part. If you have a drill press, use that,

otherwise use the drill guide that is included in the printing files.

Take your time, if the hole is not perpendicular the shaft will

be out of alignment, which can cause your quadrants to bind upon

assembly. If you need to, print a couple to make sure you

get thiis correct.

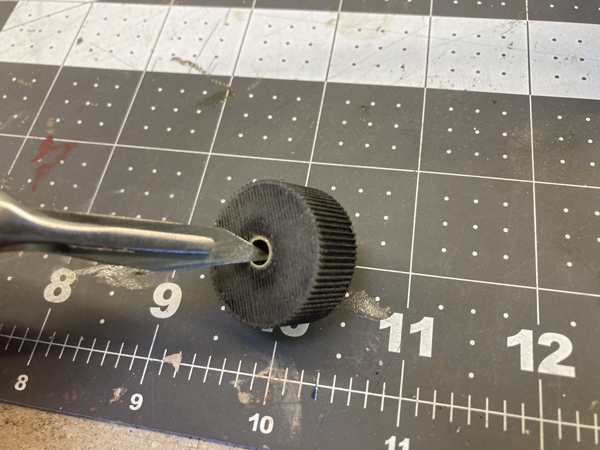

Slightly ease or chamer the end of the 7/32" tubing and insert it into

one of the quadrants. Insert into the quadrant until it bottoms

out. If you need to use a hammer to tap it in, rest the other

end of the tubing on a block of wood, and light strike the top of the

quadrant; avoid distoring the narrow opening that the potentiometer

will be inserted into. It should require a moderate amount ot of

force to seat

the tube.

Slightly ease or chamer the end of the 7/32" tubing and insert it into

one of the quadrants. Insert into the quadrant until it bottoms

out. If you need to use a hammer to tap it in, rest the other

end of the tubing on a block of wood, and light strike the top of the

quadrant; avoid distoring the narrow opening that the potentiometer

will be inserted into. It should require a moderate amount ot of

force to seat

the tube.

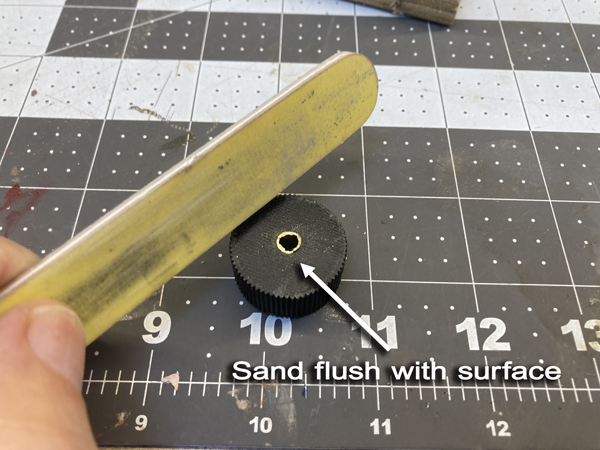

Using a razor saw, trim any tubing flush with the inner face of the

quadrant; sand or file as needed. Repeat this with the

other quadrant. Run the tip of a hobby knife around the inside of

the tube to de-burr it as needed.

Using a razor saw, trim any tubing flush with the inner face of the

quadrant; sand or file as needed. Repeat this with the

other quadrant. Run the tip of a hobby knife around the inside of

the tube to de-burr it as needed.

Sand or file the cut end of the tube flush with the face of the quadrant

Sand or file the cut end of the tube flush with the face of the quadrant

Ream the inside of the tube to remove any burr

Ream the inside of the tube to remove any burr

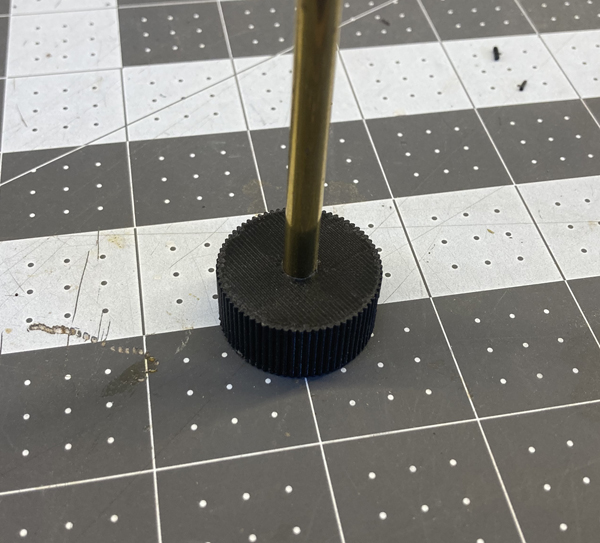

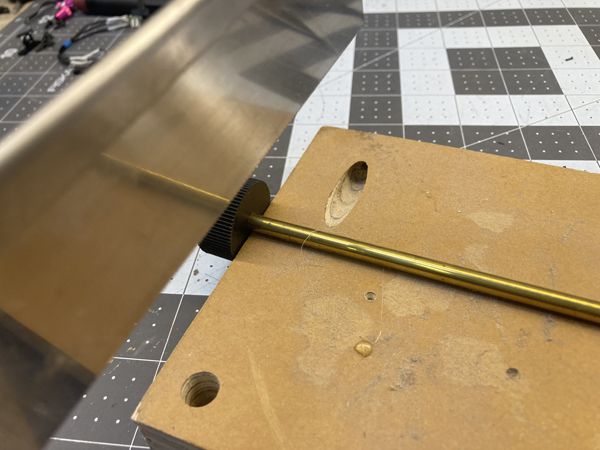

Use the Shaft cutting guide to mark out the length of the 3/16" solid

metal shaft. Mark it with a Sharpie, and trim to this line with a

razor saw (if brass) or whatever you have to cut stainless.

An alumimum miter box is handy for this step. Lightly sand

or chamfer the ends to remove any burrs. The shaft should

slide and rotate into the quadrant bushings without

binding.

Use the Shaft cutting guide to mark out the length of the 3/16" solid

metal shaft. Mark it with a Sharpie, and trim to this line with a

razor saw (if brass) or whatever you have to cut stainless.

An alumimum miter box is handy for this step. Lightly sand

or chamfer the ends to remove any burrs. The shaft should

slide and rotate into the quadrant bushings without

binding.

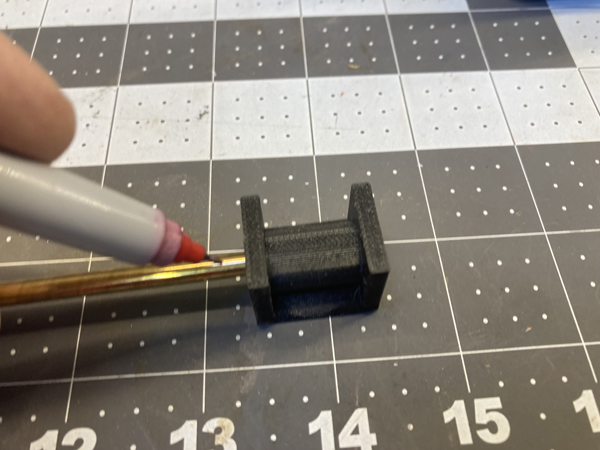

Insert the shaft into the Middle Support with Hole. It may need

to be tapped into place. The center of the support should be in

the midde of the shaft, with both ends projecting out equally.

If the fit is loose, use a small amount of thin CA glue to hold it in

place. Be sure to let it fully cure and remove any

trace of the glue on the outsde of the shafts before proceeding.

Once the glue is dry, apply a small amount of Vaseline to the exposed

portions of the shafts. A microbrush is handy for this.

Insert the shaft into the Middle Support with Hole. It may need

to be tapped into place. The center of the support should be in

the midde of the shaft, with both ends projecting out equally.

If the fit is loose, use a small amount of thin CA glue to hold it in

place. Be sure to let it fully cure and remove any

trace of the glue on the outsde of the shafts before proceeding.

Once the glue is dry, apply a small amount of Vaseline to the exposed

portions of the shafts. A microbrush is handy for this.

While you have the 3/16" drill out, clean out the holes on the side of

the quadrants where the throttle handle supports are attached to

the quadrants. Also clean out the holes in the throttle

handles. Use your 1/8" drill to clean out the holes on the

side of the throttle handles if you will be using the optional magnets.

While you have the 3/16" drill out, clean out the holes on the side of

the quadrants where the throttle handle supports are attached to

the quadrants. Also clean out the holes in the throttle

handles. Use your 1/8" drill to clean out the holes on the

side of the throttle handles if you will be using the optional magnets. Put both quadrants on either side of the Middle Support with

Hole. The hole for the throttle handle supports should be on the

radiused side of the support

Put both quadrants on either side of the Middle Support with

Hole. The hole for the throttle handle supports should be on the

radiused side of the support Check for any binding, the quadrants should rotate smoothly.

Check for any binding, the quadrants should rotate smoothly.

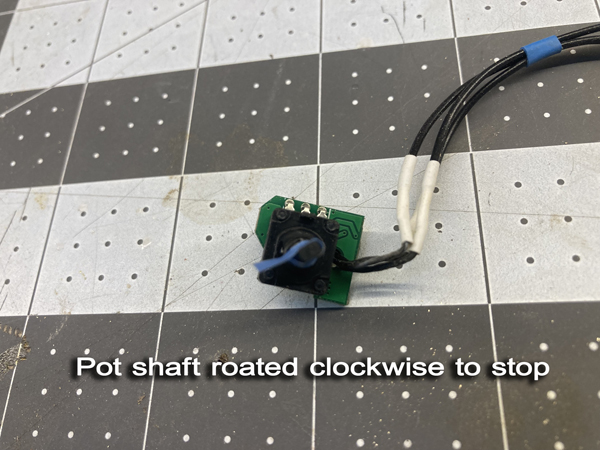

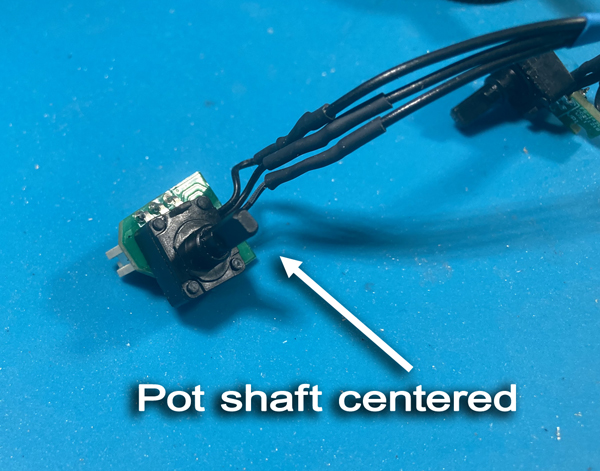

Take your two potentitomers, and center

their shafts by rotating them

one way and other until you find the center of rotation. They

should have about 100 degrees of swing, give or take, on either side to

work properly. When you have their shafts centered,

posistion the circuit boards to face inside the radio case (and away

from the throttle handle support holes)

Take your two potentitomers, and center

their shafts by rotating them

one way and other until you find the center of rotation. They

should have about 100 degrees of swing, give or take, on either side to

work properly. When you have their shafts centered,

posistion the circuit boards to face inside the radio case (and away

from the throttle handle support holes) .

.

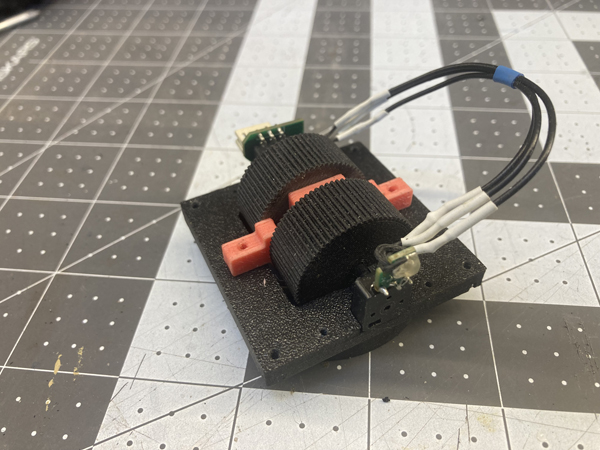

Insert the potentiometer with the larger

circuit board on the left side

of the quadrant assembly. Insert the other on the right

side. Run the wires abovc the assembly, which will be the

top of the radio case. Note that it will seat full on the first step of

the potentiometer shaft, but there will be two steps exposed.

Insert the potentiometer with the larger

circuit board on the left side

of the quadrant assembly. Insert the other on the right

side. Run the wires abovc the assembly, which will be the

top of the radio case. Note that it will seat full on the first step of

the potentiometer shaft, but there will be two steps exposed.

Put the assembly into the bezel, making sure that the potentiometers

seat into the slots provided in the bezel

Put the assembly into the bezel, making sure that the potentiometers

seat into the slots provided in the bezel

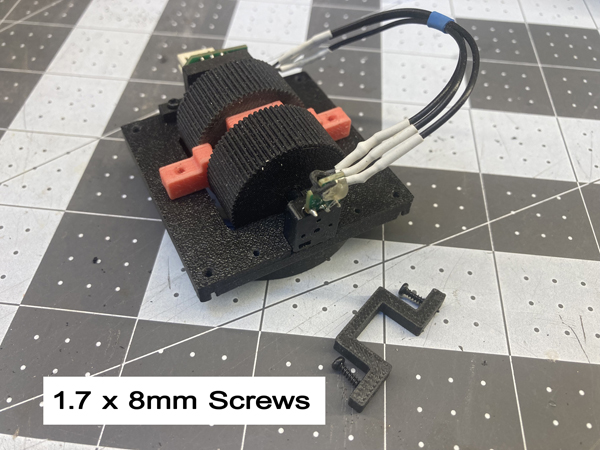

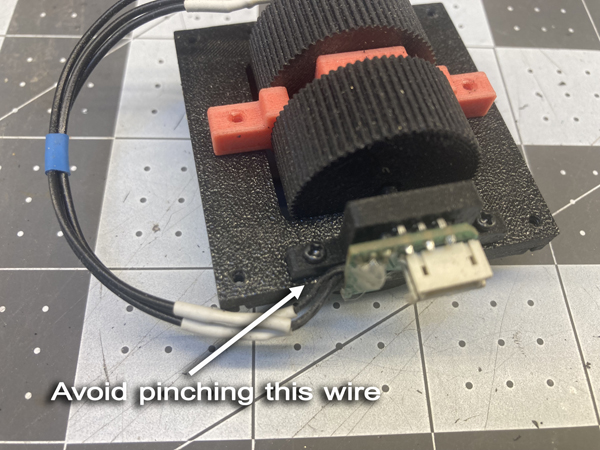

Put the Saddles over the potentiometers, making sure you clear the

wires. I found on the left side it is good to put the small

1.7mm x 8mm screw in the upper hole first, and then place it into

place, as the wiring harness can get in the way. Be very careful

not to trap or damage the wiring harness when screwing the saddles into

place.

Put the Saddles over the potentiometers, making sure you clear the

wires. I found on the left side it is good to put the small

1.7mm x 8mm screw in the upper hole first, and then place it into

place, as the wiring harness can get in the way. Be very careful

not to trap or damage the wiring harness when screwing the saddles into

place.

Depending on the tolerances of you printer, the saddles may not fully

seat, and that is Ok. They just have to prevent the

potentiomers from moving.

Depending on the tolerances of you printer, the saddles may not fully

seat, and that is Ok. They just have to prevent the

potentiomers from moving.  Insert the solid aluminum throttle sticks

into the quadrants. These should be a tight fit, so you may

have to press a bit. If it is loose, you can use a small drop of

medium viscosity CA cement to lock them into place

Insert the solid aluminum throttle sticks

into the quadrants. These should be a tight fit, so you may

have to press a bit. If it is loose, you can use a small drop of

medium viscosity CA cement to lock them into place

This is a good place to check to

make sure your potentiometer shafts were properly oriented. You

should be able to push the sticks up and down to their full

travel. If you cannot, you will need to disassemble and

re-orient the pot shafts.

This is a good place to check to

make sure your potentiometer shafts were properly oriented. You

should be able to push the sticks up and down to their full

travel. If you cannot, you will need to disassemble and

re-orient the pot shafts.  Prepare the throttle handles.

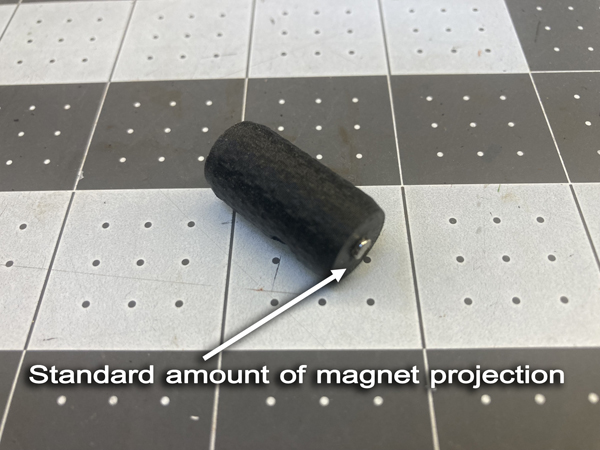

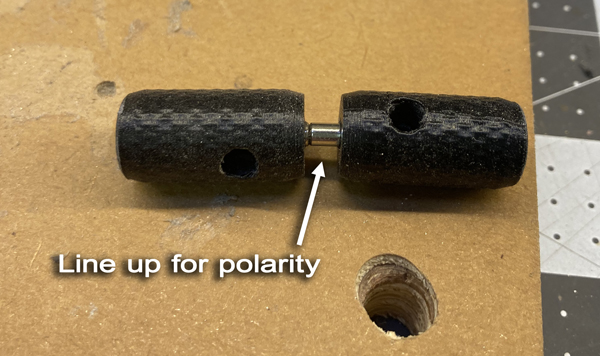

If you want to have rare earth magents installed so the sticks can move

together, insert a 1/8" diamter by 1/4" long rare earth magnet into the

hole at the end of one handle. It should be a press

fit. Then take the other magnet and let it attack to the

first; this ensures that you don't have the polarization

reversed. Then insert this into the second throttle handle

and seat it. The magnets will project slightly from each

throttle handle. If you find that they require more force

that you want to disengage, then you can use shorter magnets and set

them flush with the end of the handle. You can experiment to find

the best amount for your needs.

Prepare the throttle handles.

If you want to have rare earth magents installed so the sticks can move

together, insert a 1/8" diamter by 1/4" long rare earth magnet into the

hole at the end of one handle. It should be a press

fit. Then take the other magnet and let it attack to the

first; this ensures that you don't have the polarization

reversed. Then insert this into the second throttle handle

and seat it. The magnets will project slightly from each

throttle handle. If you find that they require more force

that you want to disengage, then you can use shorter magnets and set

them flush with the end of the handle. You can experiment to find

the best amount for your needs.

Insert the throttle handles onto the stick

shafts. Your Gimbal is now assembled

Insert the throttle handles onto the stick

shafts. Your Gimbal is now assembled

Now insert the bezel assembly into the radio. You can feed in one

of the throttle handles first; it will fit when completly

assembled. If you find it easier to do so, you can remove one or

both of the throttle handles. When the gimbal is seated on

the four posts inside the radio case, you should feel it seat into

place.

Now insert the bezel assembly into the radio. You can feed in one

of the throttle handles first; it will fit when completly

assembled. If you find it easier to do so, you can remove one or

both of the throttle handles. When the gimbal is seated on

the four posts inside the radio case, you should feel it seat into

place. Use 4 2.3mm x 10mm screws to attach the

gimbal to the case. Again, no need to over-torque these

screws.

Use 4 2.3mm x 10mm screws to attach the

gimbal to the case. Again, no need to over-torque these

screws. Plug the gimbal plug back into place.

Plug the gimbal plug back into place.

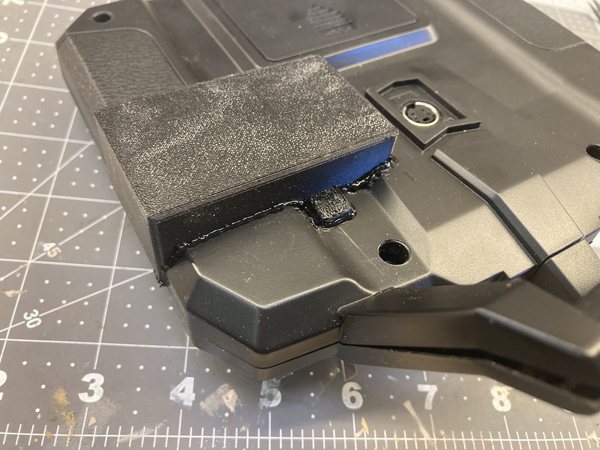

Cut the hole slightly inside the

markings. You can use a variety of ways to cut the cover;

razor saw, chain drill a series of holes, a dremel tool equiped with a

saw blade, whatever is safe and comfortable for you to do, With

the undersized rough hole cut, sand to fit.

Check with the printed cover often; you are

aiming for a nice friction fit. the back cover will sit on the

two "ears" and the lip at the rear.

Cut the hole slightly inside the

markings. You can use a variety of ways to cut the cover;

razor saw, chain drill a series of holes, a dremel tool equiped with a

saw blade, whatever is safe and comfortable for you to do, With

the undersized rough hole cut, sand to fit.

Check with the printed cover often; you are

aiming for a nice friction fit. the back cover will sit on the

two "ears" and the lip at the rear.

Return to Warship Models Underway

1309

Please write me with your comments!

Please write me with your comments!

This page maintained by Kurt Greiner. Version 1 10/25